Introducing Scope Capture

Justin McCoy | December 02, 2021

Determining the safe life left in a rope has always been an issue for those who use it in just about any operation. It is a problem that has spanned millennia and countless generations of seafarers and users of rope. The knowledge of how to use rope and maintain its integrity is not one that is learned from textbooks, but passed on through experience. What has resulted is a mass of users that do not know how to inspect the product accurately, and industries that rely on haphazard judgement calls for its safe use.

Manufacturers of rope products have tried to supply industries with tools, such as specific rope knowledge classes and rope comparison charts, however much of these efforts have had little impact on the ability to safely monitor and maintain rope systems. This is because the standard best practice of manual visual inspection is not a form of measurement, it is a qualitative assessment.

In the case of OCIMF's MEG4, it is recommended that ropes be replaced once they reach 75% of their residual break strength. How are operators supposed to comply if there is not an understanding of when exactly the rope reaches that point? What if we could know precisely when to replace a rope and why? What if compliance to a standard was measurable and maintainable?

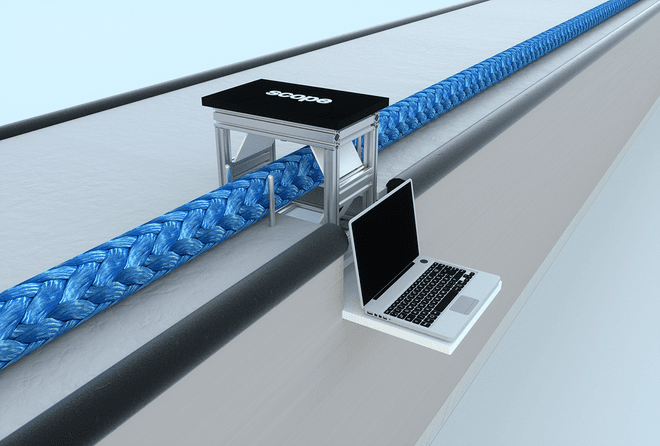

For manufacturers of rope products that desire to see a safer standard than manual visual inspection, we are proud to announce Scope Capture. Using this technology, rope manufacturers are able to train manufacturer and product-specific deep learning neural networks to automate the inspection of their rope products.

Scope Capture gives manufacturers the ability to offer product specific, damage recognition models to their clients. When clients use a Scope device, it references those models in order to make an accurate assessment of the rope product in real time.

In the near future, users of rope will be required to use products that can be inspected accurately because compliance will be measurable and maintainable. Further, they will seek out products that have accurate recognition models and will spend more for the assurance and safety that compliance promises. Loyalty to products will be awarded to those manufacturers that maintain and build accurate models over those who do not.

Scope Capture empowers manufacturers to precisely craft deep learning recognition models for any product they manufacture, enabling new rope applications to be approached, and old applications to be approached in a new way. Only now can manufacturers offer the assurance that the health of their rope products can be measured. Only now can you know exactly when and why a rope needs service, needs to be replaced, or a rope fails. And only with Scope Capture.

––––