Meet Vision², the mobile AI inspection system redefining how utility crews inspect their stringing lines, winch lines and hoist lines— without ever leaving the job site.

Trusted by Industry leaders

The Challenge of Rope Inspection

$500k

per hour

Unplanned downtime cost per failure

$28k

per inspection trip

Average roundtrip cost of transporting stringing equipment

2-3

critical failures quarterly

Frequency reported by major utility contractors

Manual inspection is expensive, time-consuming and unreliable. It's time improved safety measures made it into the field - where the real work happens.

The Solution

Meet Vision², the mobile AI system that brings rope inspection directly to the job site — no logistic headaches, no downtime, and no guesswork.

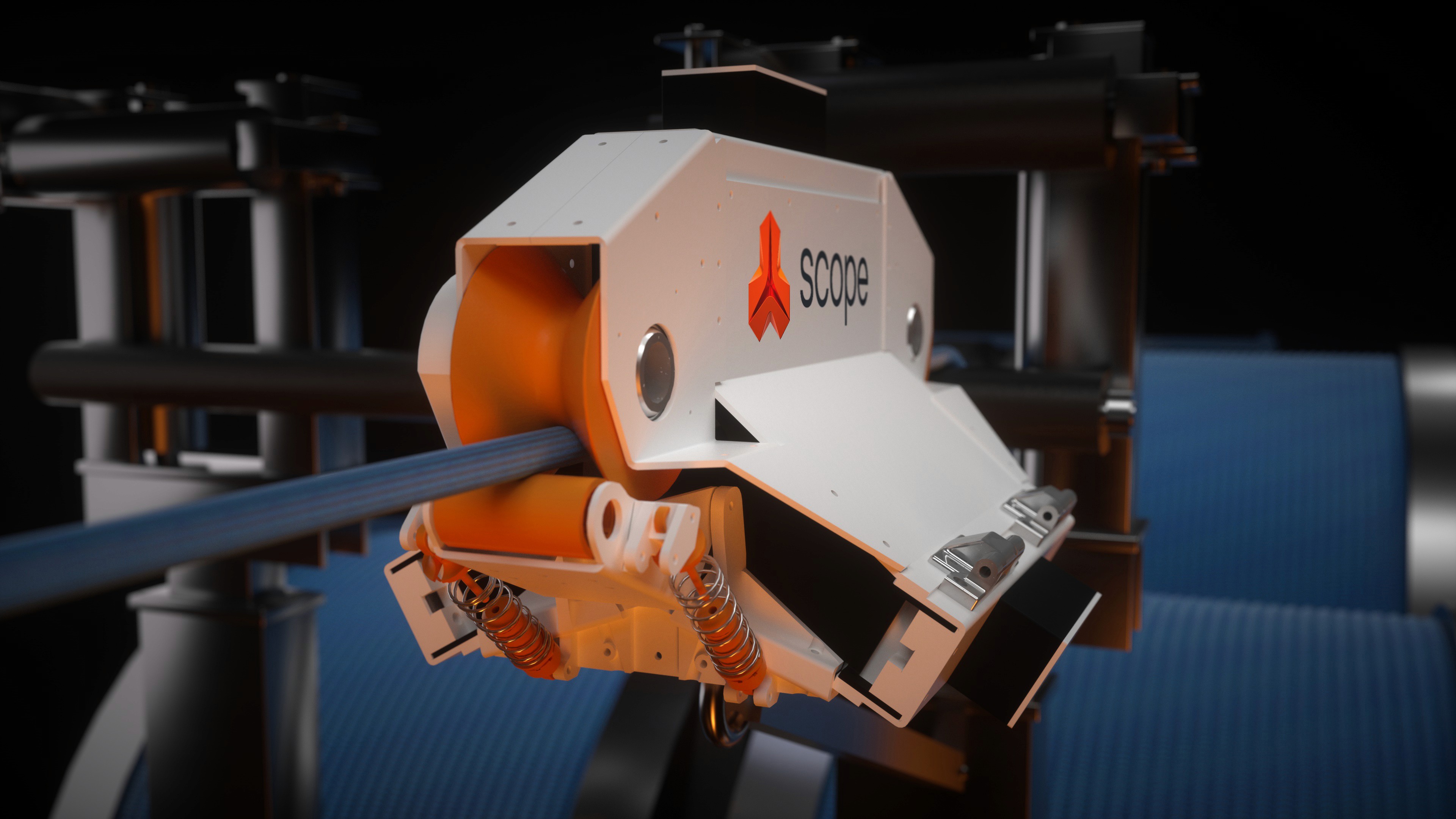

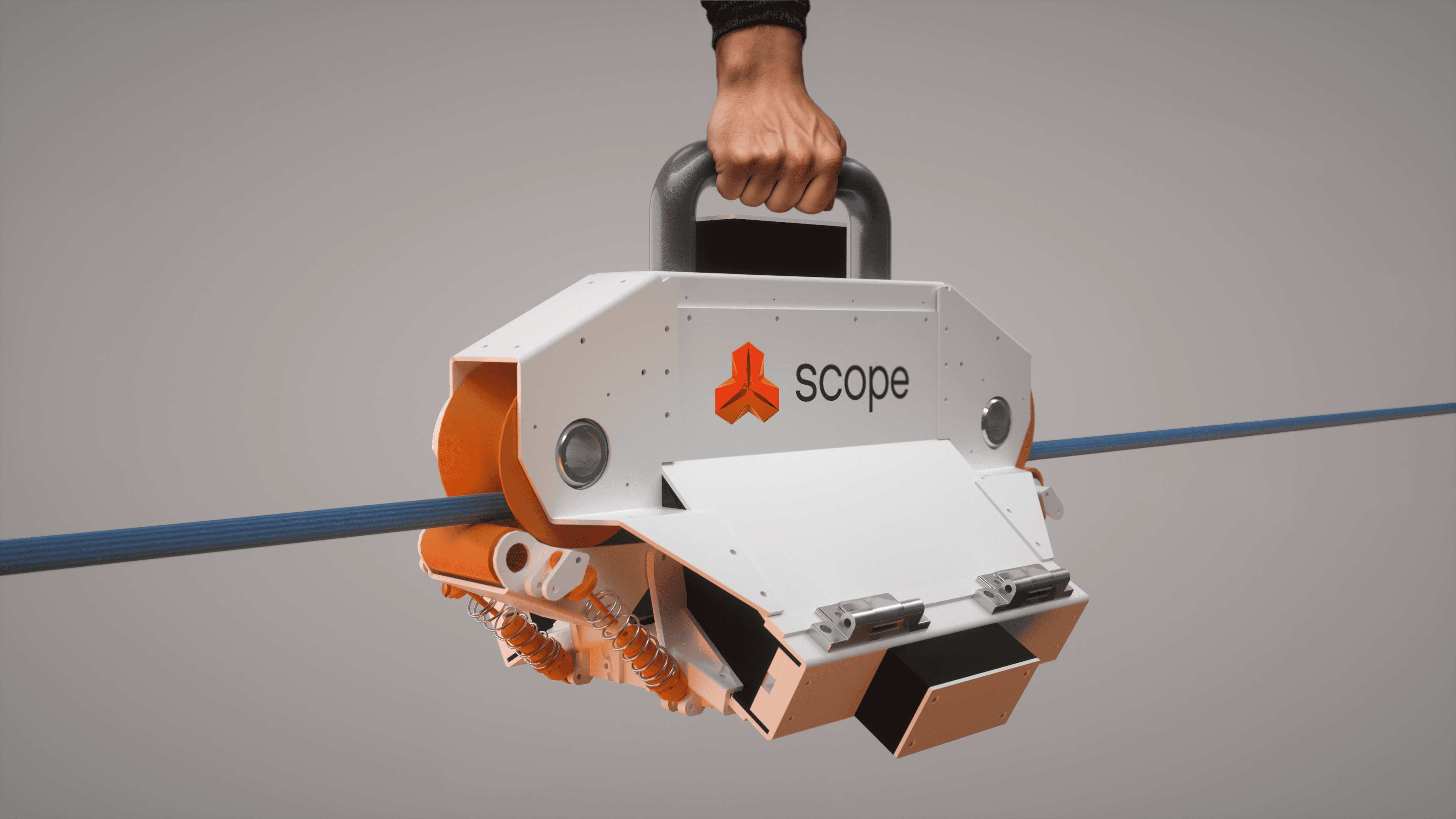

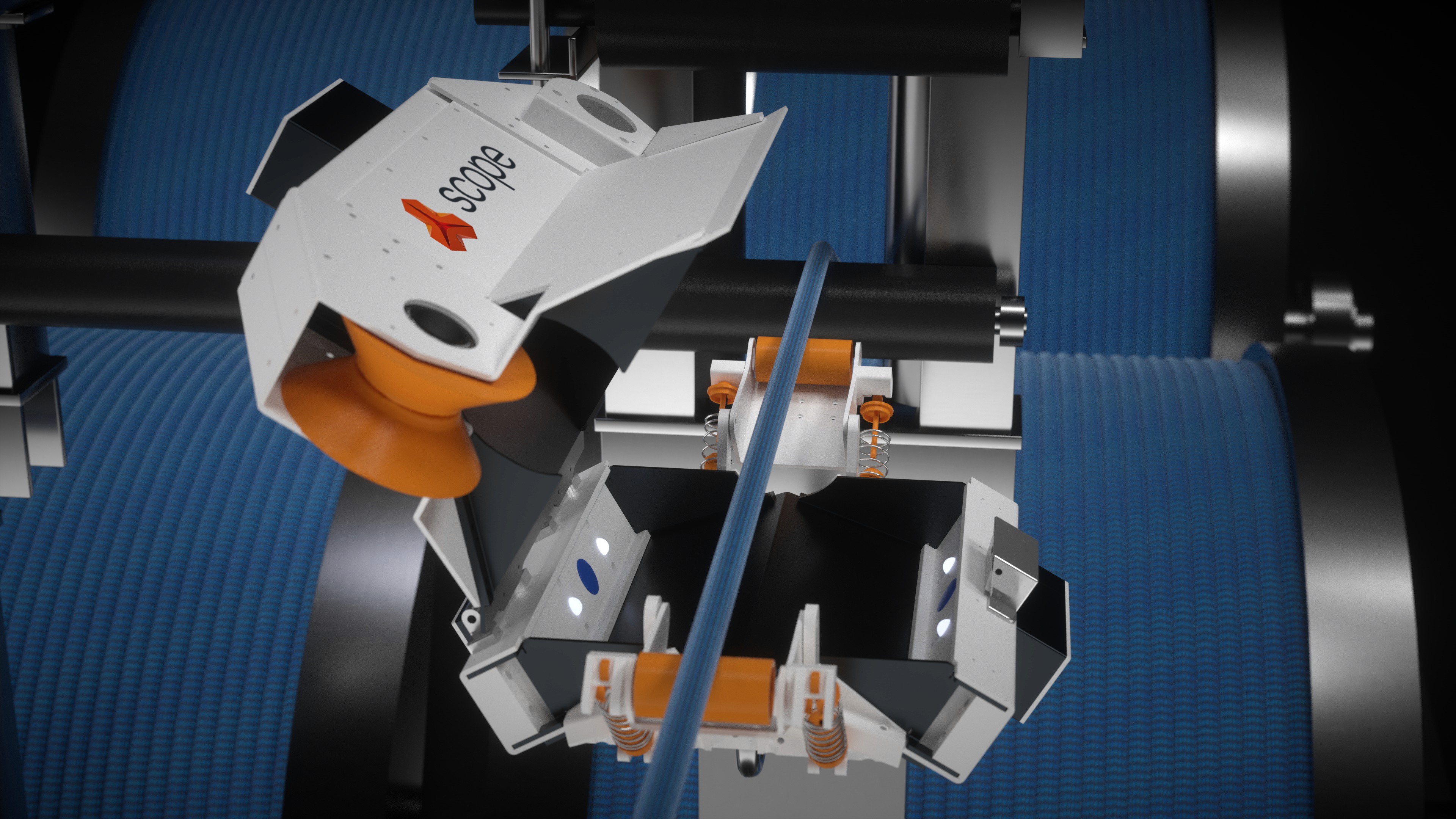

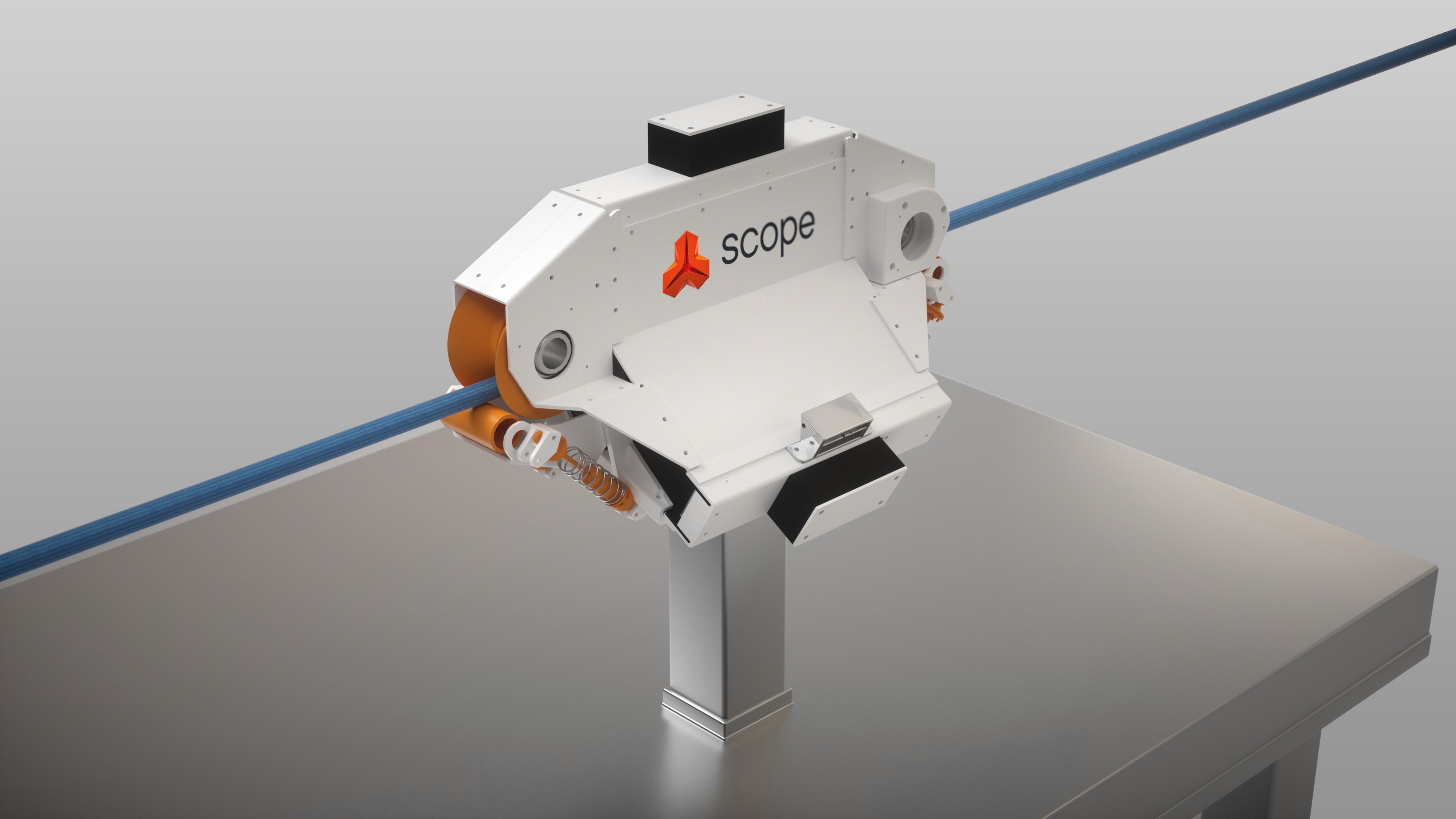

Technology Inside Vision²

The Vision2 imaging system has been designed from the ground up to provide the highest resolution and clarity possible at speeds up to 8 mph. Accomplish detailed inspections in a fraction of the time it would take to complete manually.

All inspection data is available online instantly, as soon as an inspection is completed, enabling expert review and compliance reporting from anywhere the job needs to be done.

The Vision2 system removes subjectivity from the inspection process and delivers crisp insights on rope health when it matters the most, in the field of operation.

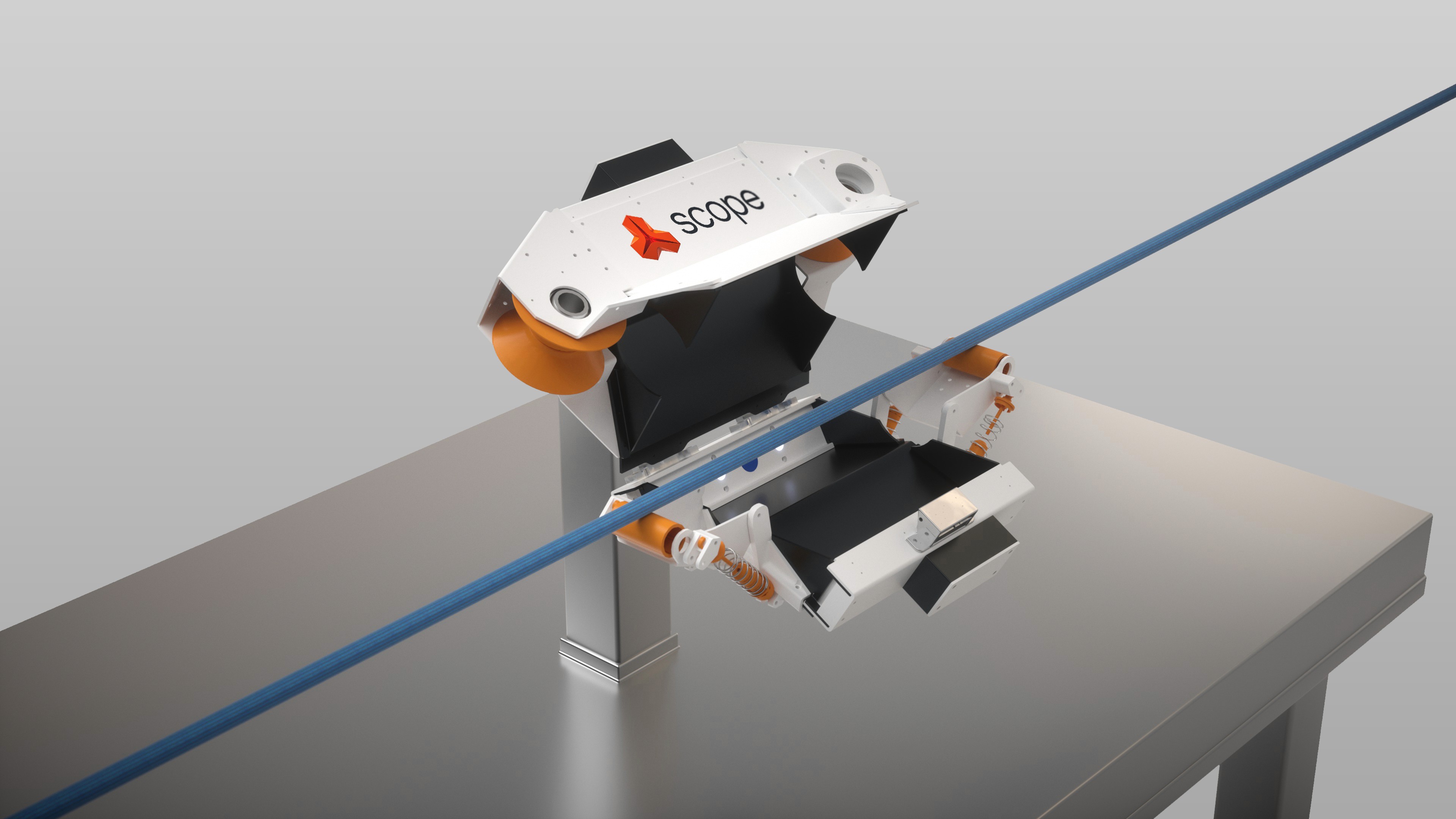

The Vision2 system has been designed with linemen, for linemen. With the rugged clamshell design it is simple to keep clean and easy to use.

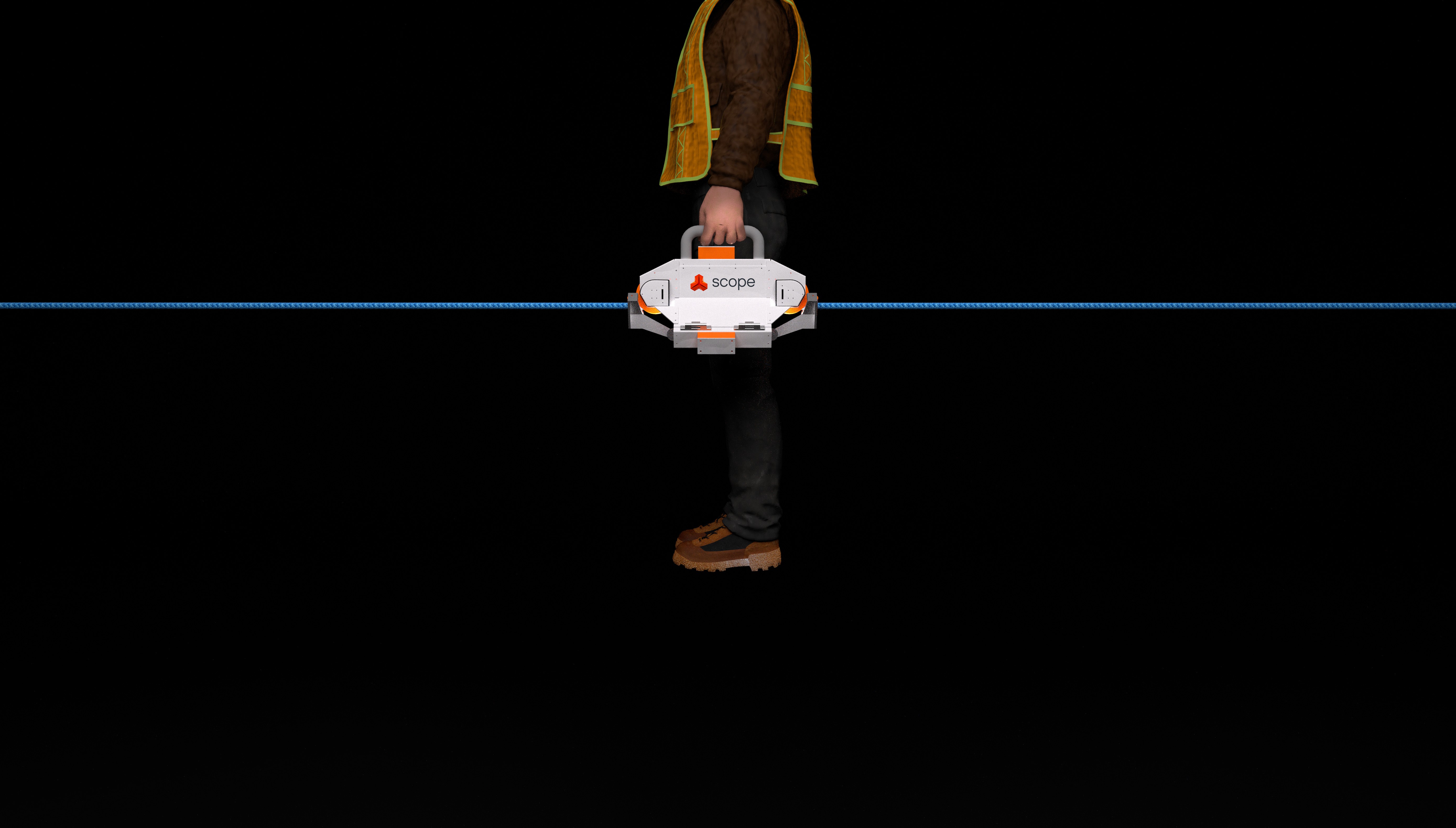

Mobility & Versatility

Vision² is an inspection system that can adapt to how you need to work and integrates seamlessly into daily operations.

01

In-line mode

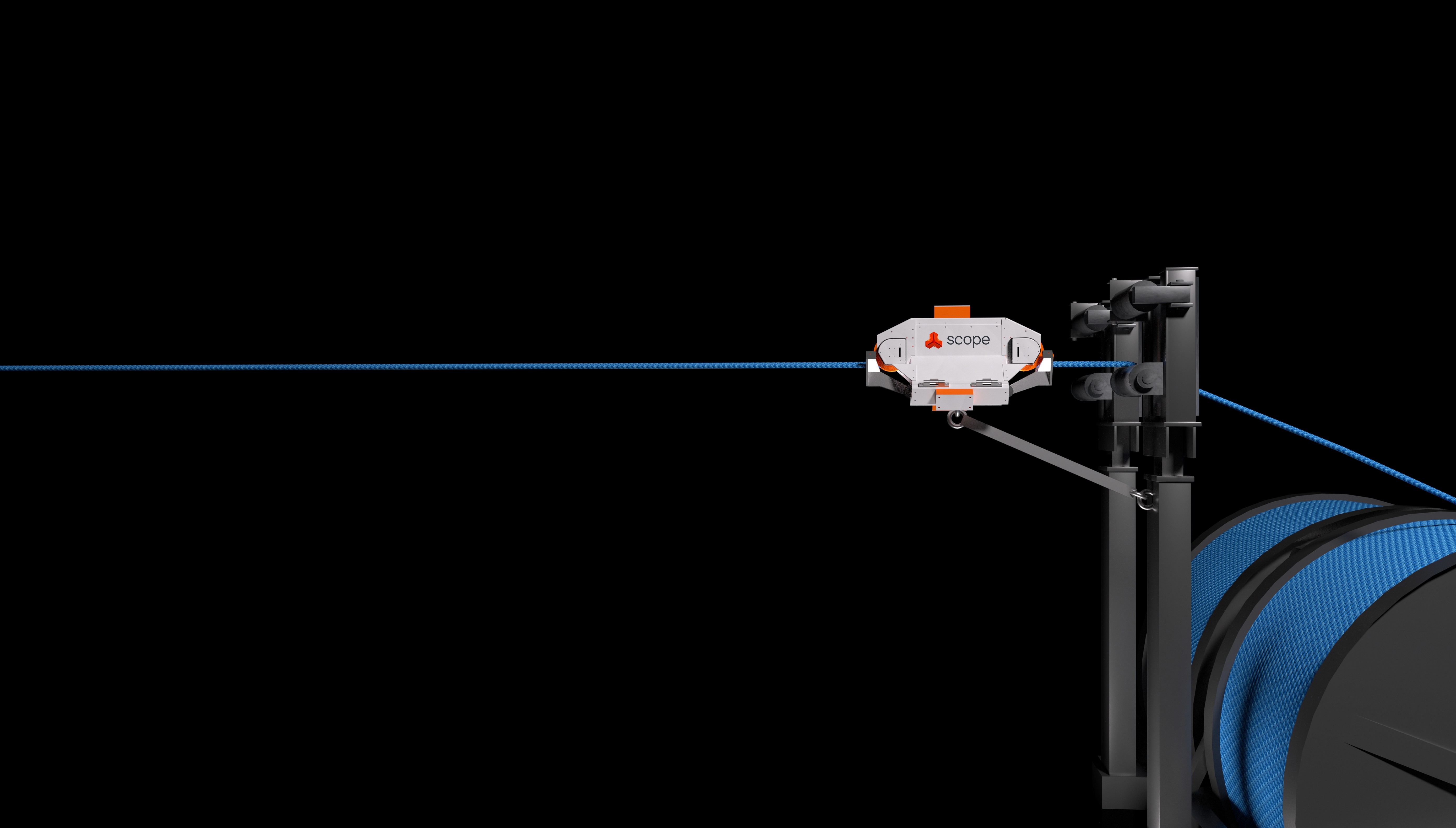

02

In-hand mode

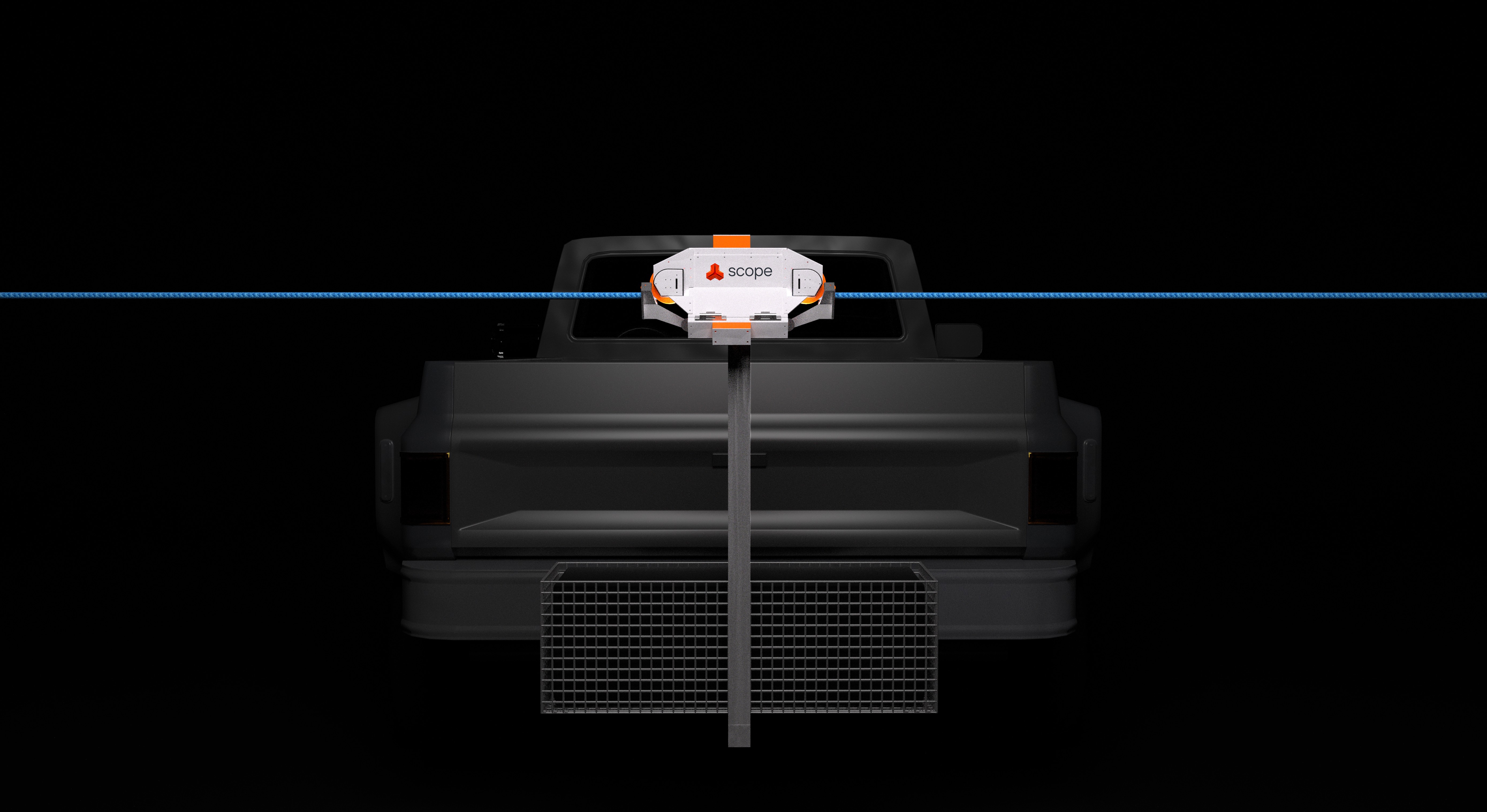

03

In-field mode

Every line, on every piece of equipment, can now be inspected as part of normal operations, improving safety, efficiency, and compliance.

From the Field

Scope

4,169 followers

2h

•

We're hiring a Robotics Electrical Engineer team to facilitate our customer needs across synthetic fiber,, wire and our broader… more.

Scope

4,169 followers

2d

•

Shoutout to Entergy for hosting our team at their Safety Summit! Deploying technology to support employee & contractor safety… more

Scope

4,169 followers

3w

•

We’re excited to welcome SWOS: Synthetic Rope Solutions SL-12 into the Scope ecosystem!

Scope

4,169 followers

3w

•

Scope is proud to highlight American Equipment as they continue to ramp up coverage for inspection of stringing…more.