A Note from the CEO

Justin McCoy | March 22, 2023

Over the past year, you may have noticed our relative silence—a decision we made intentionally.

We took this time to refine our purpose, direction, and strategy to better serve our customers and ensure our organization was on the right path. Throughout this process, we've had to adapt, reflect, and make tough decisions. Rapid iteration and ultra-tight feedback loops were pivotal in overcoming the extraordinary challenges that innovation presents.

In focusing our efforts, we prioritized the most crucial aspect of any new technology: the people who use it.

We embarked on a journey to better understand our customers' met and unmet needs. At Scope, our mission is to transform manual visual inspection—a process integral to countless products and processes across various industries.

Our co-founder, Mike Poroo, possesses extensive expertise in synthetic rope, which served as a valuable starting point. While synthetic rope inspection may seem like a niche domain, each application is entirely unique and often holds great significance in terms of safety and reliability.

Determined to address the most pressing unmet needs, we sought an area where we could potentially achieve the ideal product-market fit. This led us to the utility stringing industry, which presented a unique set of challenges and opportunities.

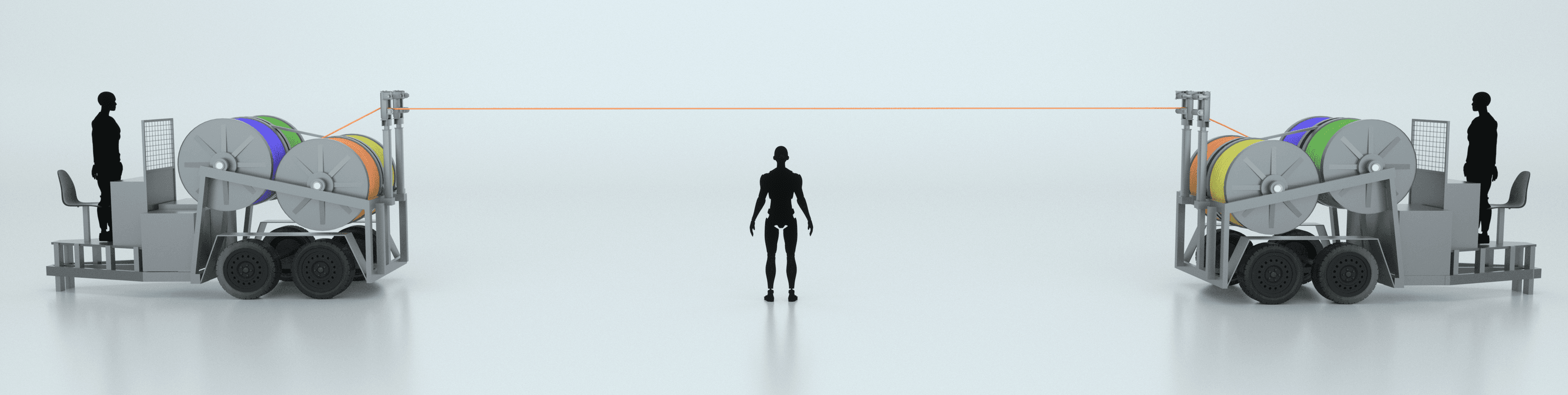

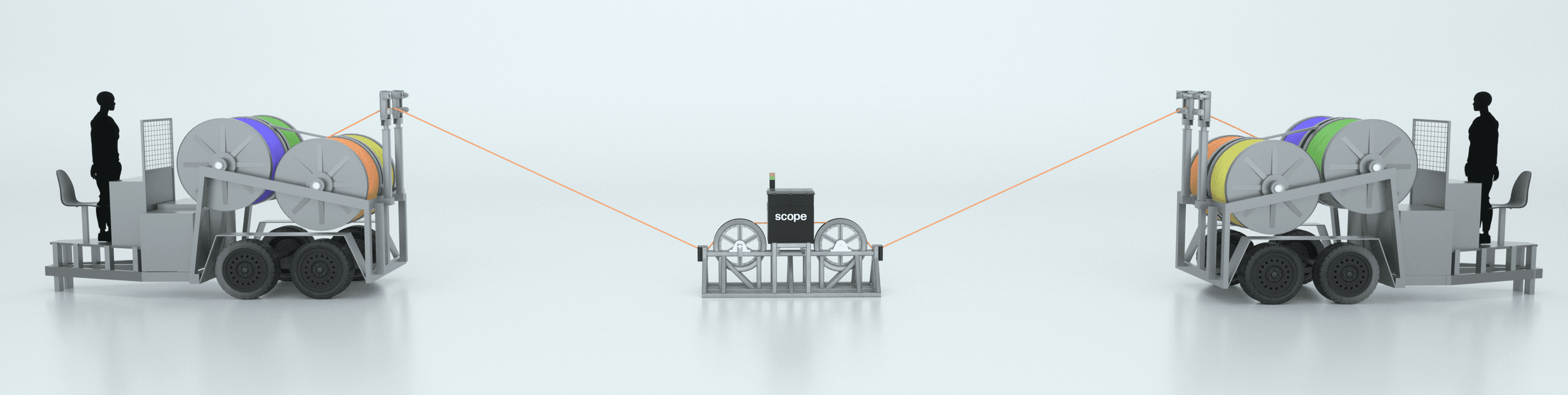

Utility stringing operators face the daily task of inspecting miles of synthetic rope, often while it is being rewound onto a drum at speeds of up to 3 mph. This high-speed process makes it difficult for operators to make accurate, instantaneous decisions about the rope's condition, rendering repair planning nearly impossible. Complicating matters further, there are no established standards for rope health or maintenance in this critical application, and failures can lead to severe property damage and safety hazards.

Our search led us to a group of industry visionaries eager for change. These individuals recognized that innovation, rather than optimization, would create a safer work environment and improve operational efficiency. These trailblazers and their organizations have played a crucial role in the development and implementation of our technology.

Thanks to these visionaries, we have deployed Scope inspection systems at locations across the country.

While each location is unique, they all share a common passion for raising the bar on rope inspections and maintaining a critical safety factor. Maintaining a factor of safety is not possible with visual inspection alone.

At Scope, our goal is to revolutionize manual visual inspection on a grand scale. We aim to achieve this not by replacing human workers but by augmenting their capabilities with advanced technology. People remain at the heart of our mission, values, and approach. As we look forward to the coming year, we are excited to share more about our journey at Scope. We are eager to unveil new developments, forge partnerships, and continue making a meaningful impact on the industries we serve.

This is only the beginning. - JMc