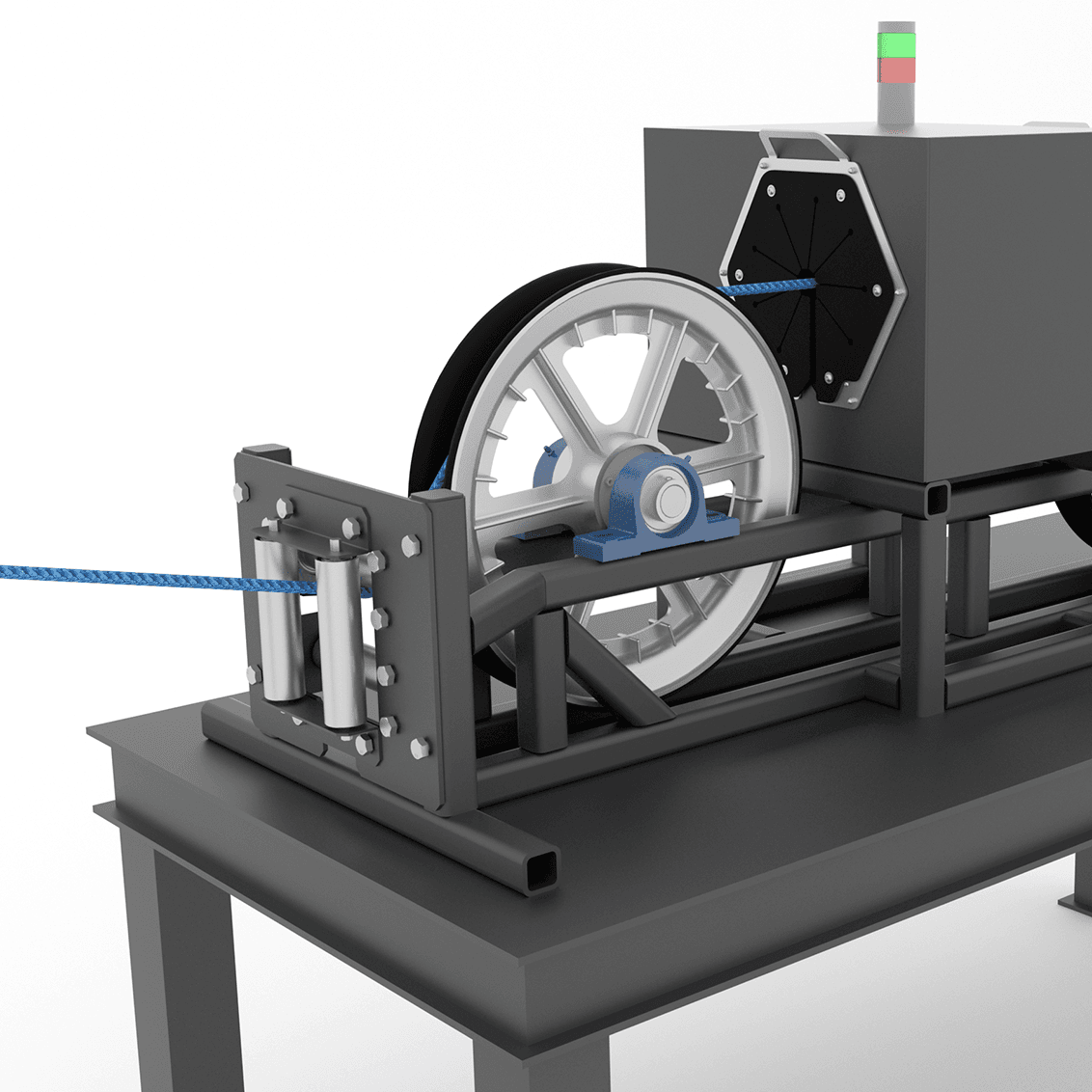

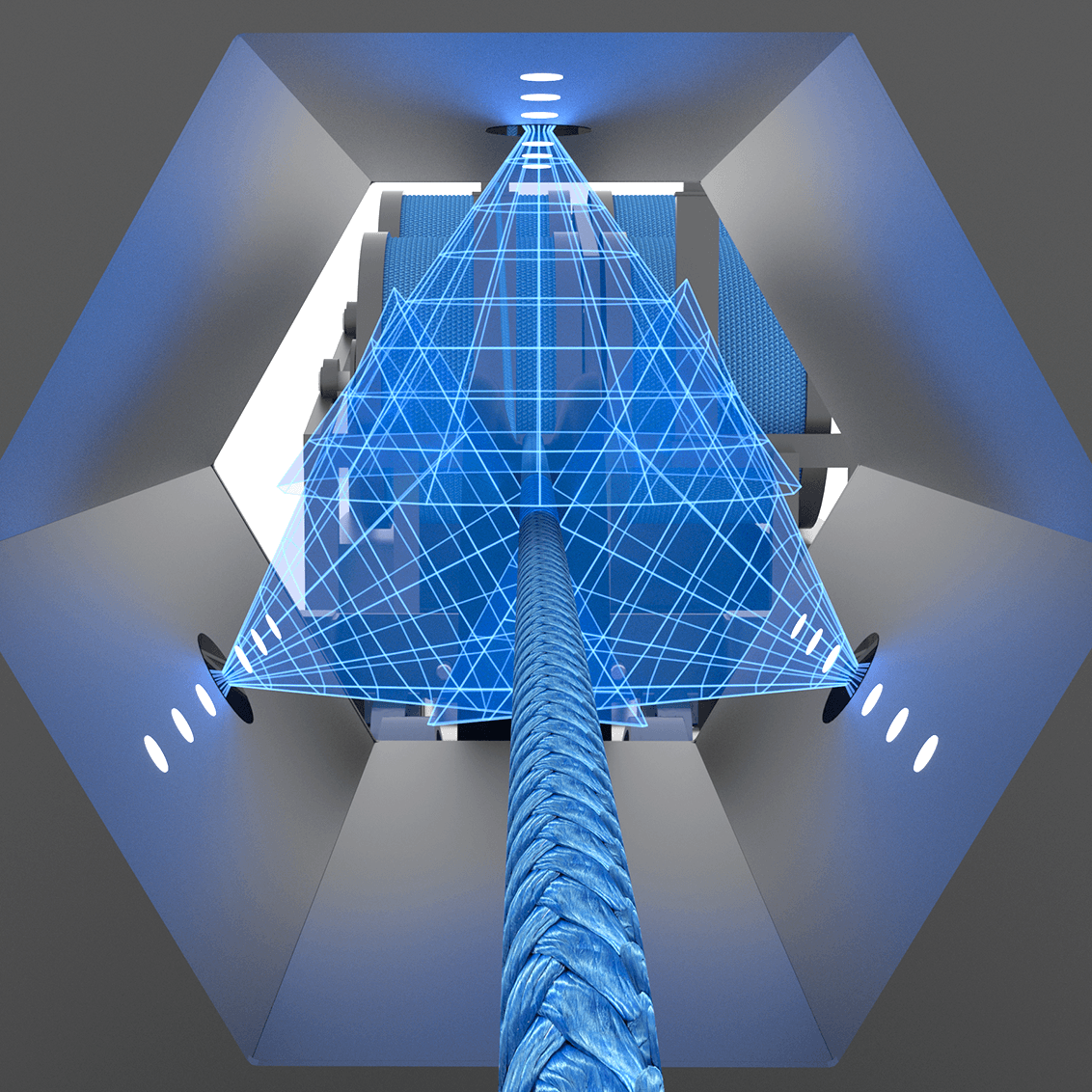

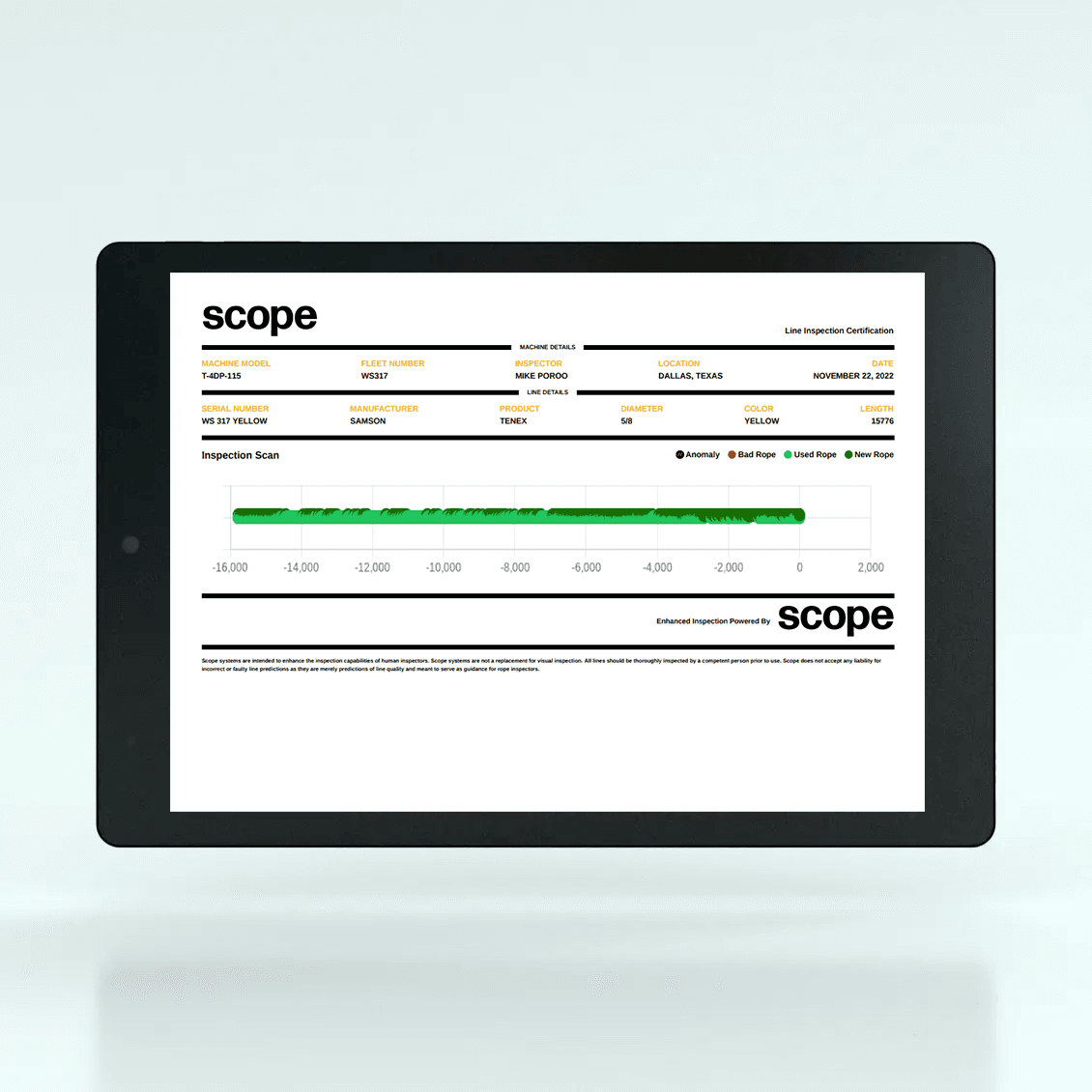

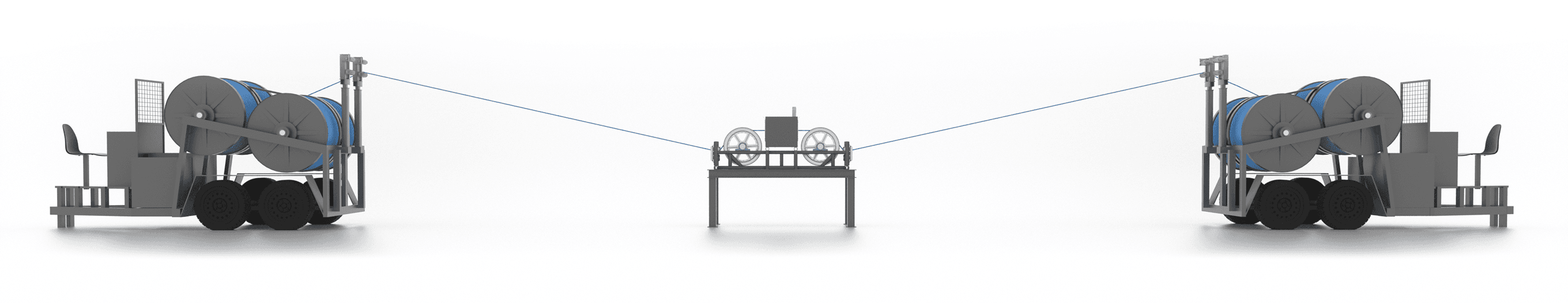

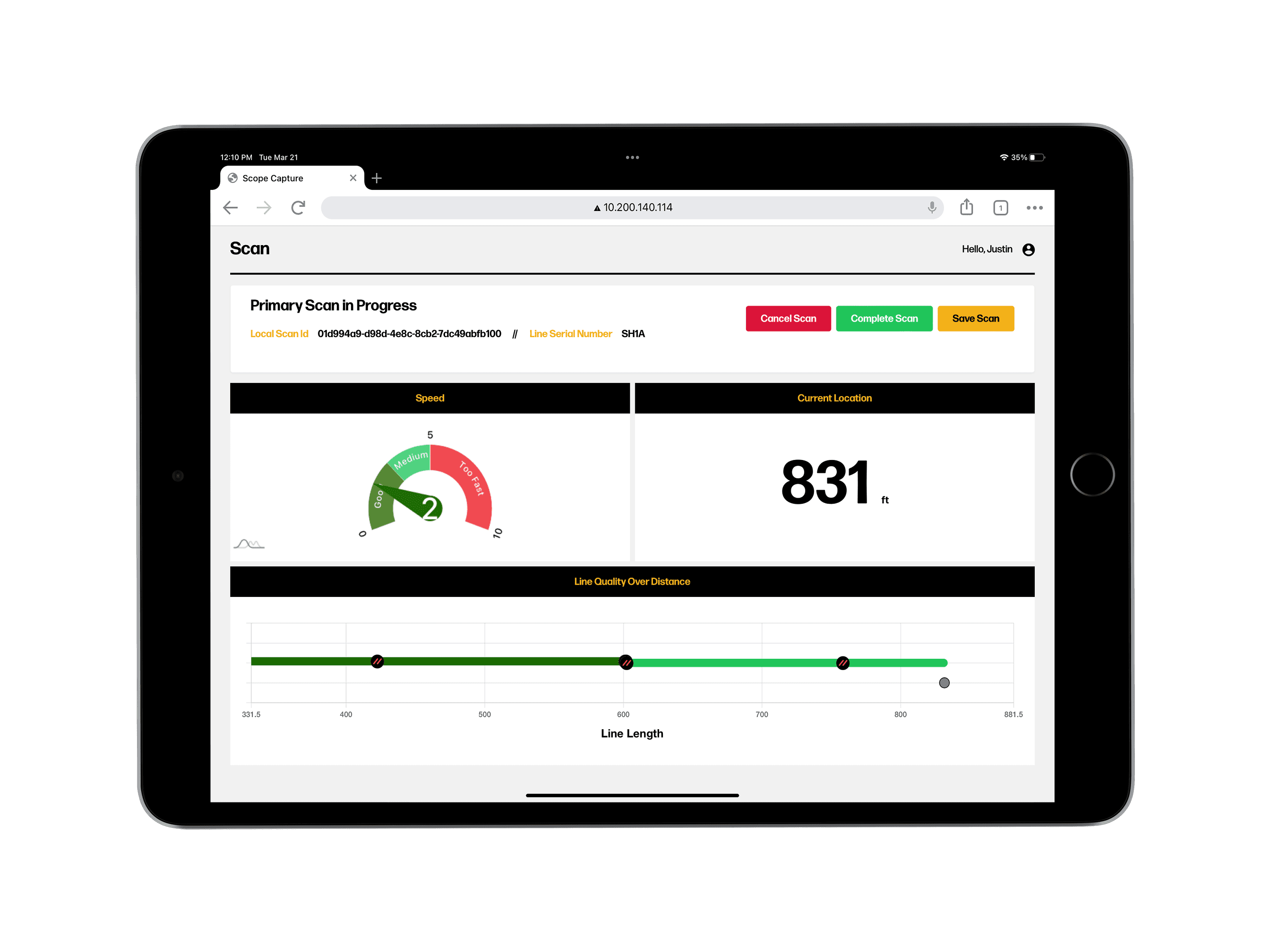

Manual visual inspection is not a practical solution for inspecting thousands of feet of rope. With the Scope Line Quality Platform, operators can spend their time addressing the issues instead of looking for them. With Scope, operators can identify signs of wear and tear, damage, or defects in synthetic ropes that may not be easily visible to the human eye. Early detection of such issues can prevent accidents, equipment failure, and potential injuries to workers.