Capture for Safer Operations

Justin McCoy | March 10, 2022

Currently, there is zero recognizable compliance around the safe life remaining in a rope. Let me repeat this. Worldwide, there is not a realizable or maintainable level of compliance for when a user should retire a fiber rope.

Why is this?

In order for compliance to be realized, a specific metric of health must be met and maintained. Currently, there is no such metric. In order for a metric to exist, the health must be quantifiable and measurable. This means that a tool must exist to do the measuring.

Without a tool, the only possible outcome is a subjective and qualitative assessment, otherwise known as a manual visual inspection. In studying the human behavior around the visual inspection of rope, you will quickly see a lack of consistency and a massive variance between individuals grading the same rope subject. Simply put, people are just not very good at judging a rope’s health.

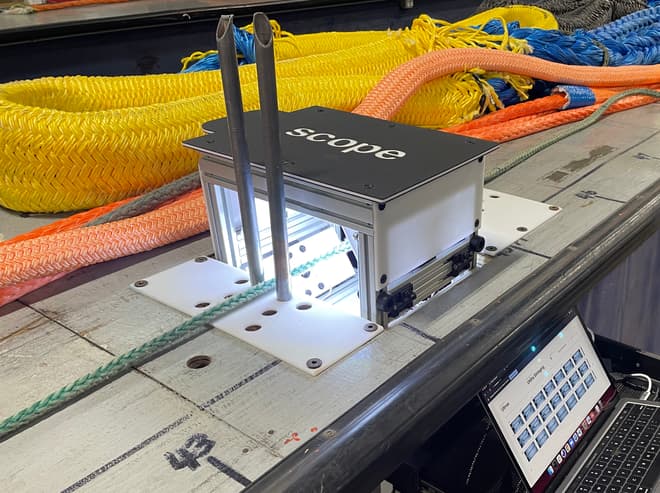

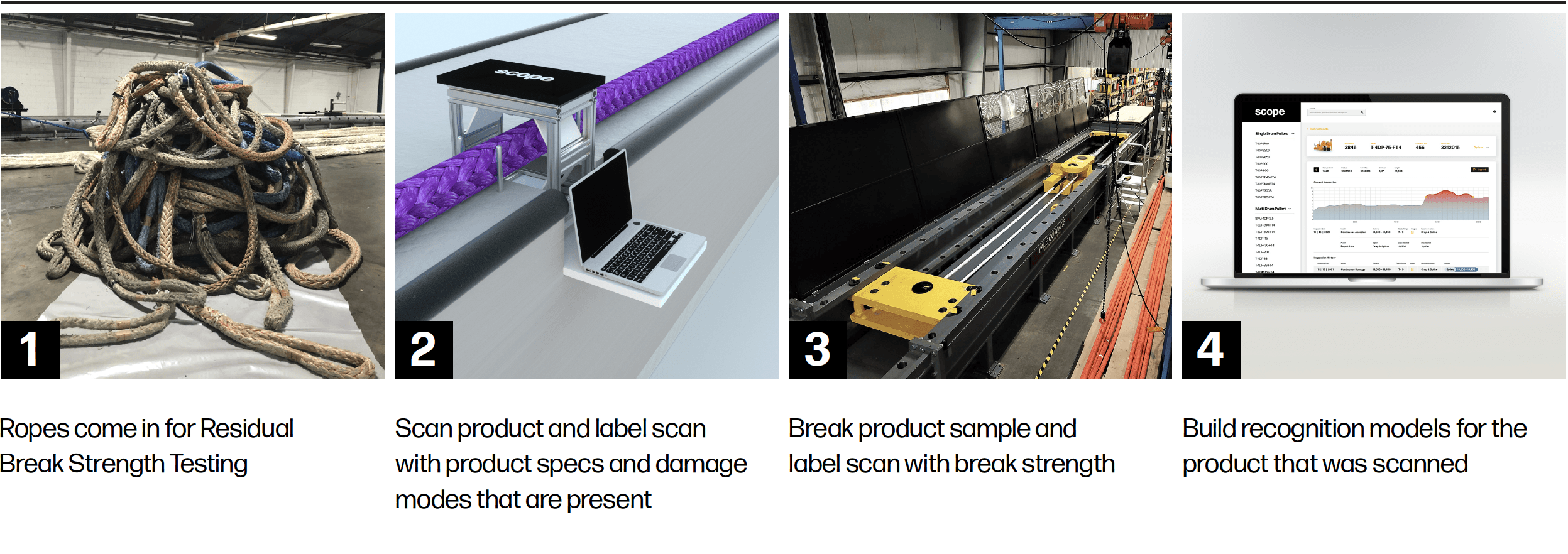

Today, Scope took the first step in providing safer operations for users of rope products with the completion of our alpha product, Scope Capture, a tool for building deep learning software that measures the health of a rope.

Until now, there was no form of measurement for the quality of a rope, and that was a problem. Especially for users and operators that have highly critical rope applications in ‘cannot fail’ circumstances.

Scope Capture empowers manufacturers of rope products to build and train highly accurate damage recognition models that are proprietary to their own products. A recognition model is a Deep Learning Neural Network that has been trained to recognize the visual characteristics of failure modes that can exist in a rope, such as abrasion and cut strands. These Deep Learning Neural Networks, when trained and paired with an in field Scope device, can inspect rope products in real time with a higher than human accuracy.

Empowering rope manufacturers to build and maintain their own Deep Learning Neural Networks, trained specifically for their products, enables their customers to have a reliable way to inspect those products at any time. We believe this is important for manufacturers as we believe that in the near future, customers will be required to use products that have such networks built around them.

When customers can accurately inspect their ropes anywhere, anytime, and can maintain their lines to a specific level of health, everyone who has a stake in the safety of the operation can breathe a bit easier. When the data behind those scans become actionable insights, operations become more efficient and hazardous incidents become avoidable. When a level of compliance is realizable and maintainable, an entire industry can operate safer.

Scope, clearly safer operations in 2022.

--