Introducing Scope Control

Justin McCoy | December 01, 2021

Before today, understanding the health of a rope product was painful, if not impossible. The inspection of a critical rope application relies on human-visual inspection, which means that someone inspects the rope by hand and uses their best judgement to determine if the rope is safe for use. This is the standard best practice for every rope application world wide. Rope manufacturers have tried to provide tools, such as educational programs and rope comparison charts, to assist in this manual inspection. However, without a tool to actually measure quality, the safety of the operation ultimately relies on a person’s ability to make an accurate assessment, one that they may or may not be trained to do successfully.

Further, without a common metric, how the quality of a line is recorded and reported typically results in hand-written inspection reports or excel documents that are not useful for understanding health trends or line quality at scale. Operators that have multiple systems of lines in play during operations are essentially flying blind to the quality of their lines.

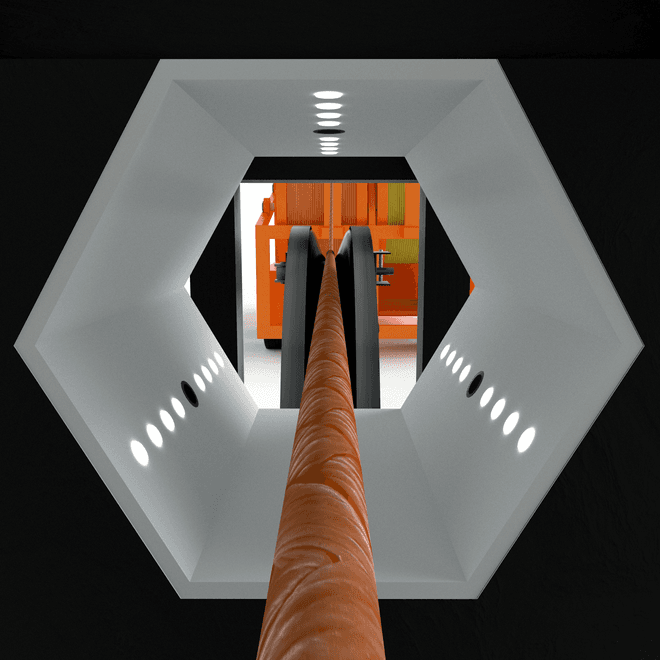

Today, we are proud to announce Scope Control. With this technology, for the first time ever, operators can measure the health of a rope product in real-time, in-line with their operations. This capability is a game-changer for companies working towards safer operations that meet and exceed compliance regulations because unlike manual visual inspections which are completely qualitative, measurement with Scope Control means that realizing and maintaining a safe level of compliance is now possible. If a line must be retired at 75% of its life, it is no longer a guessing game as to when a rope reaches that threshold. With Scope Capture, the line can be retired precisely at the moment it falls out of compliance, with custom notifications immediately alerting the parties concerned.

Synthetic and steel wire rope have a long way to go. For most applications, products are still inspected by human eyes. If you want to see, understand or fix something, you have to be there yourself, the moment an issue arises. In these manual operations, the amount of valuable data that is not collected, trapped in hand-written reports or excel documents, or is simply over-written is overwhelming. Scope’s mission is to extract actionable information from all of the data surrounding these operations with artificial intelligence, transforming it into a trail of usable and useful information that can be used to quickly find root issues, increase risk transparency, and ultimately create safer operations.

If you lead a team that uses rope products and would like to learn more about how our system can help you and your team find and fix issues, improve data transparency, and establish safe operations, please contact us for a demo.

––––